Printing tissue: Human skin models

Printing human skin tissue models is one of the clear benefits of 3D bioprinting technology. In this blog, we will recap what Jim Engström and Isabella Bondesson had to say about 3D printing skin in a recent seminar about Isabella’s project.

Why 3D bioprint tissue skin models?

Enhancing work in the area of 3D bioprinting skin tissue models opens up a lot of areas of improvements, for research as well as product testing. Some of these include:

- Learning how to print more complex and biomimetically relevant tissue models

- Increasing our ability to examine how cells interact with each other in an environment similar to the “real thing”

- Reducing the need for animal testing by providing relevant models

All in all, developing validated human skin tissue models extends possibilities for data that is more accurate, reliable and observable in a lab.

How do you print a skin tissue model?

Isabella’s project used three major steps to print the skin tissue models.

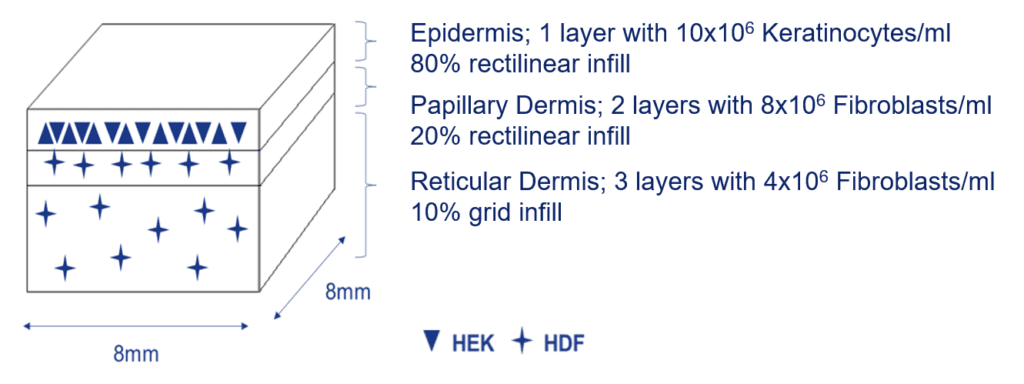

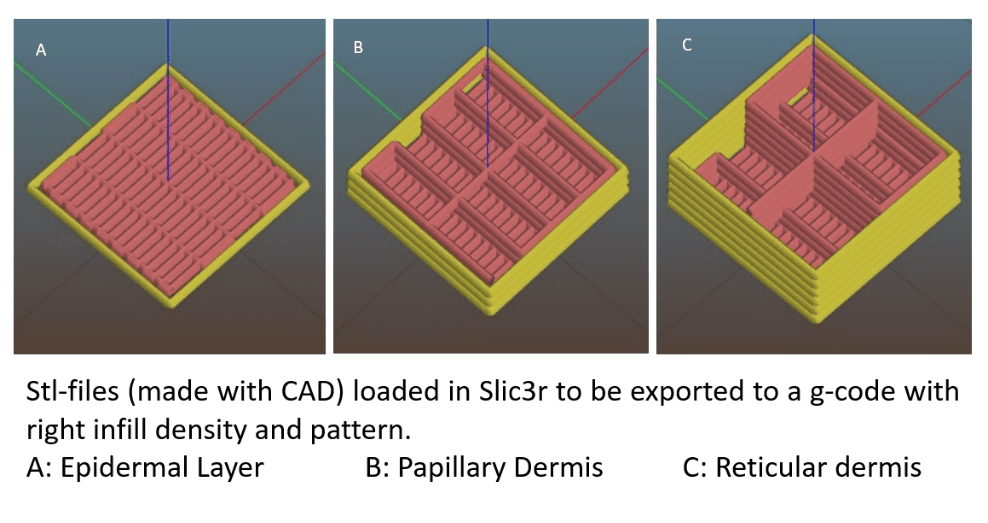

Step 1: Creating the model

To create the model, Isabella made a blueprint based on the presentation and makeup of human skin.

Human skin has two distinct layers – the epidermis and the dermis. The dermis itself has two layers with different cell concentrations, so Isabella’s blueprint had a total of three layers.

Step 2: Cultivating the model

Cells need bioink to replicate their natural environment, and Isabella wanted to identify the best CELLINK bioink for printing skin. She picked two that she thought would work well:

CELLINK-RGD: This bioink interacts with cell-surface receptors and ensures cell adhesion.

CELLINK-SKIN: The fibrin in this bioink promotes angiogenesis, and is critical for functions like homeostasis and wound healing.

She mixed each bioink with the keratinocytes and fibroblasts, and then cultivated the mixtures for two weeks.

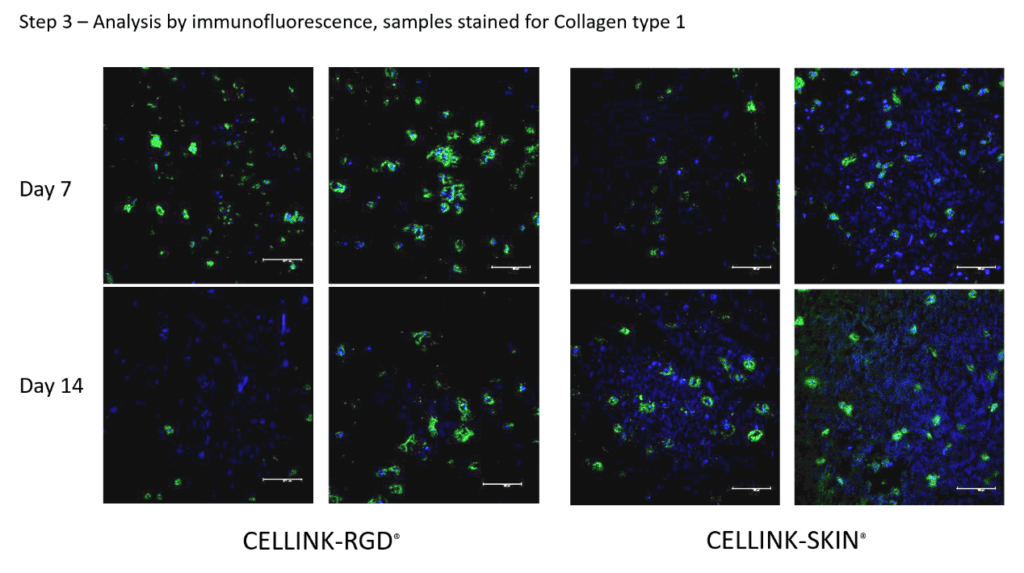

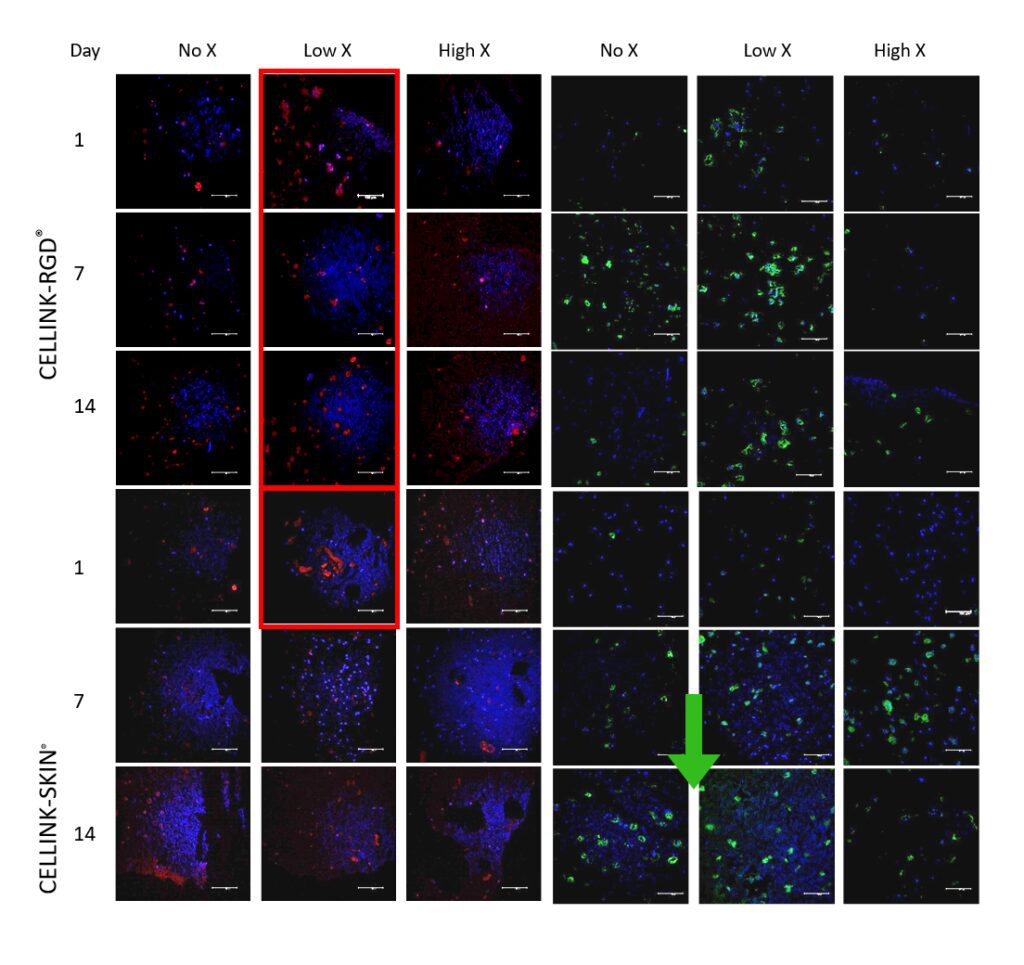

Step 3: Validating the model

To validate the model, Isabella tested the cultures for cellular activity. She used immunofluorescence to stain keratinocytes and collagen type 1 cells, and noted two observations:

a) CELLINK-RGD maintains keratinocyte activity

b) CELLINK-SKIN yields superior fibroblast morphology.

How do I get started?

With these results in mind, Isabella listed a few bioinks that are well suited for printing skin tissue models.

- CELLINK FIBRIN and CELLINK SKIN. These are based on nanocellulose and alginate, and crosslink with an ionic solution.

- GelXA FIBRIN and GelXA SKIN. These are based on gelatin and xanthan gum. They can be crosslinked with UV light or an ionic solution.

More on printing skin models

Since Isabella’s project on printing human skin, CELLINK has created a lot more content on 3D printing skin.

Webinar: A Guide on 3D Bioprinting Skin

Webinar: 3D Bioprinting Pipeline of a Full Thickness Human Skin Model

AppNote: 3D Bioprinting Skin Tissue Models Using Primary Cells