What’s the difference between 3D printing and bioprinting?

Both 3D printers and bioprinters mechanically extrude a specific substance to build a predefined structure. However, they are not designed to use the same materials or print the same things.

3D printers have been around relatively longer. They can print materials like polymer resins, metal, plastic and rubber, and the medical industry can use them to create surgical instruments, implants and more.

Bioprinters create fundamentally different structures

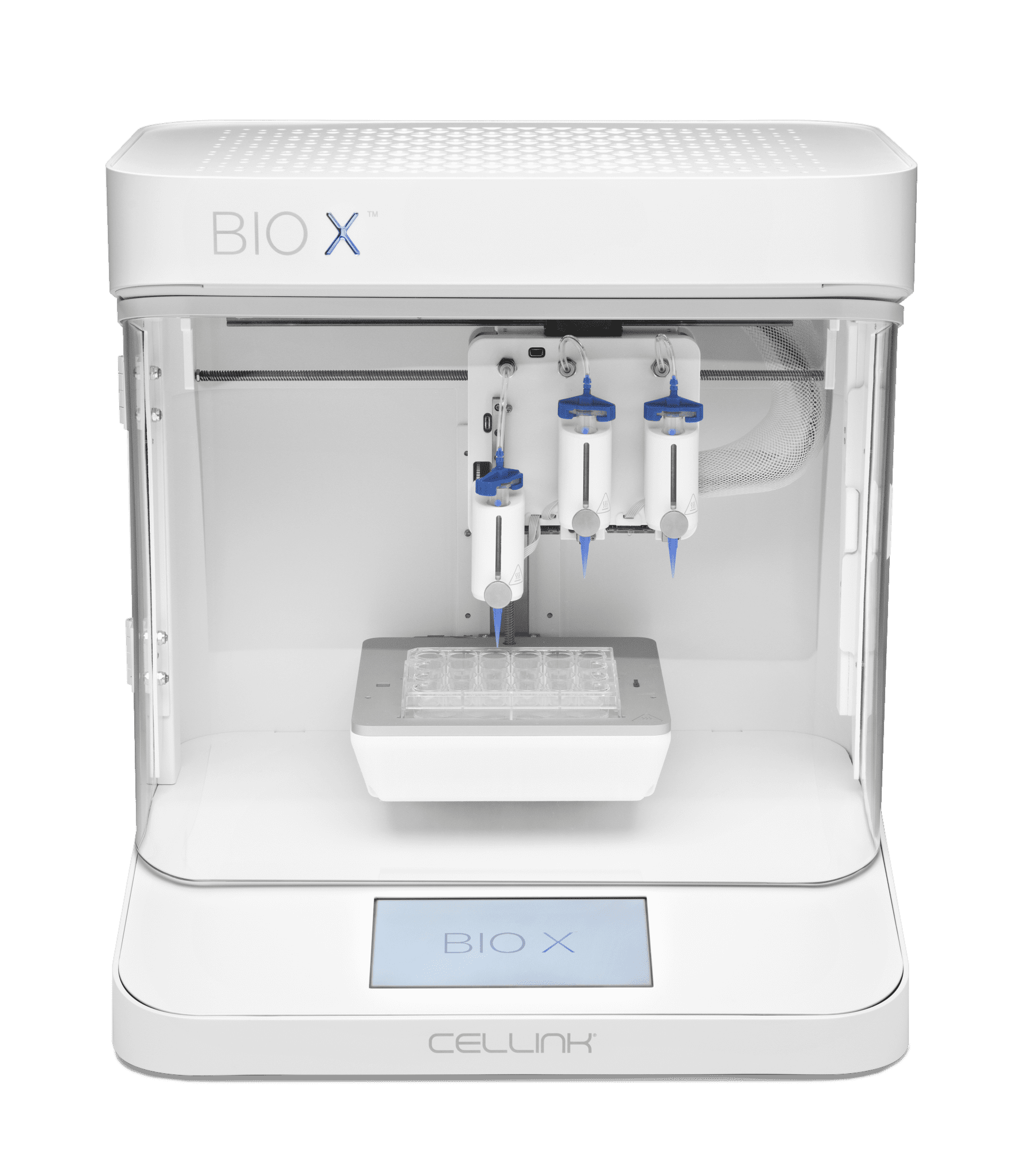

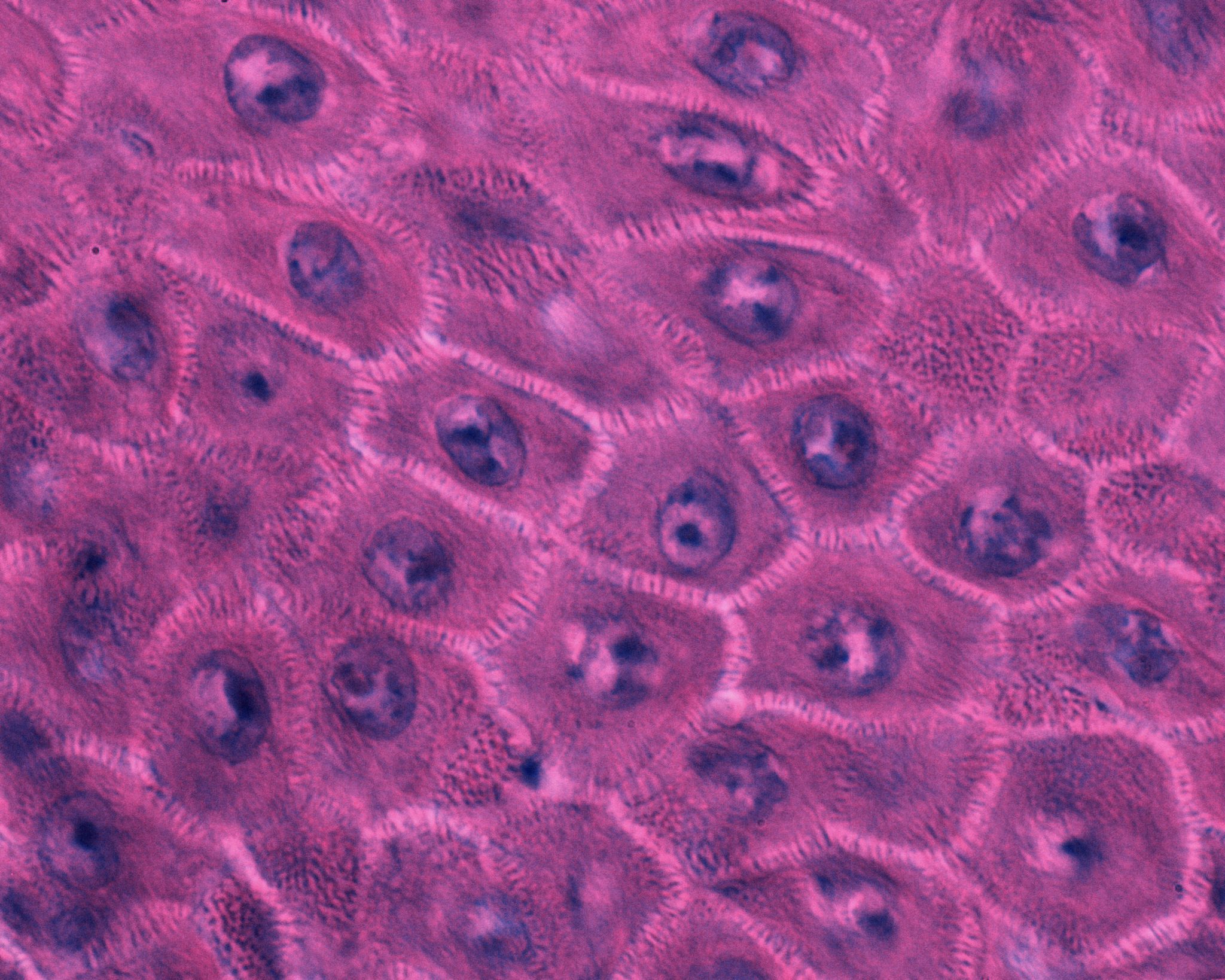

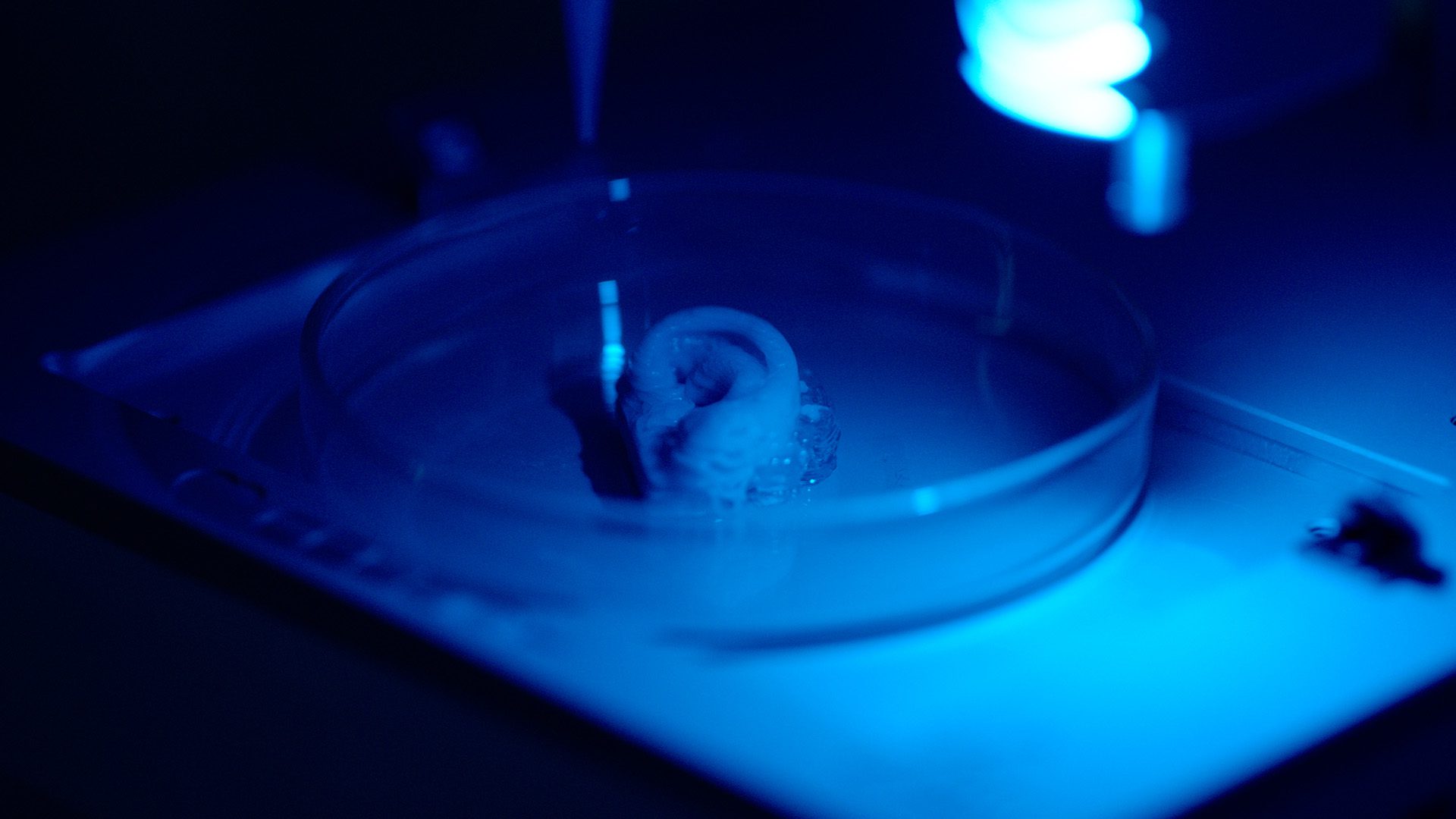

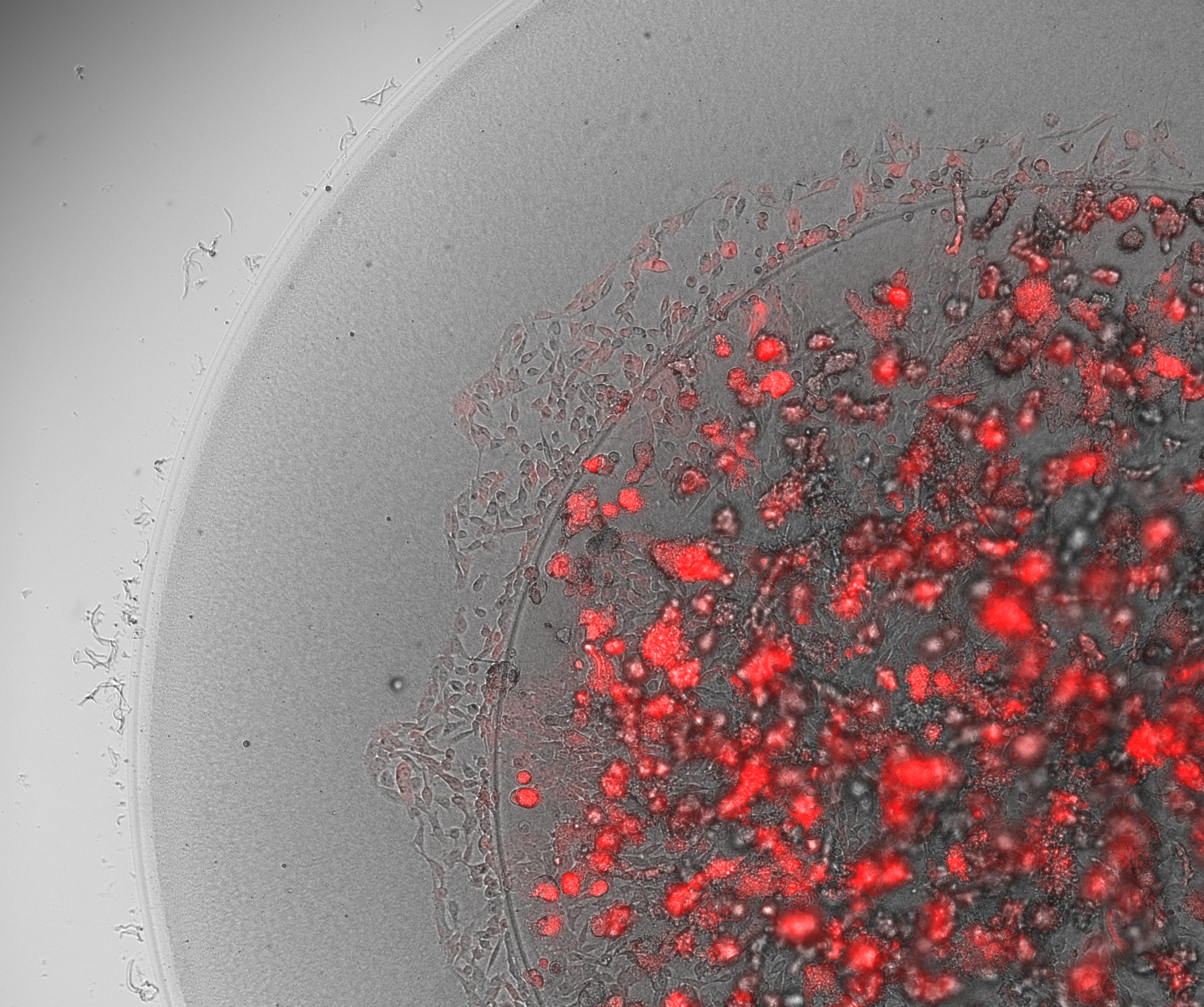

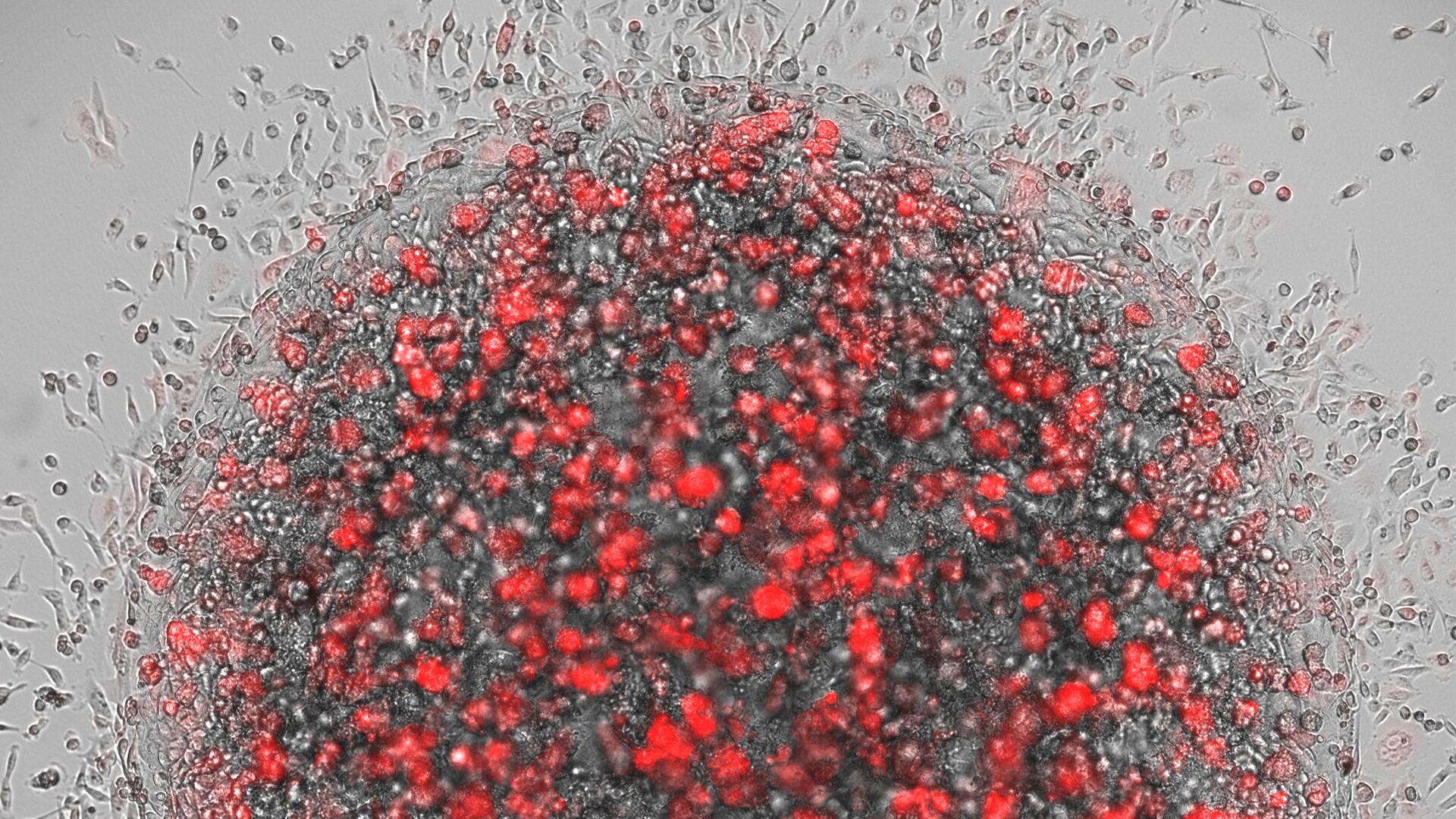

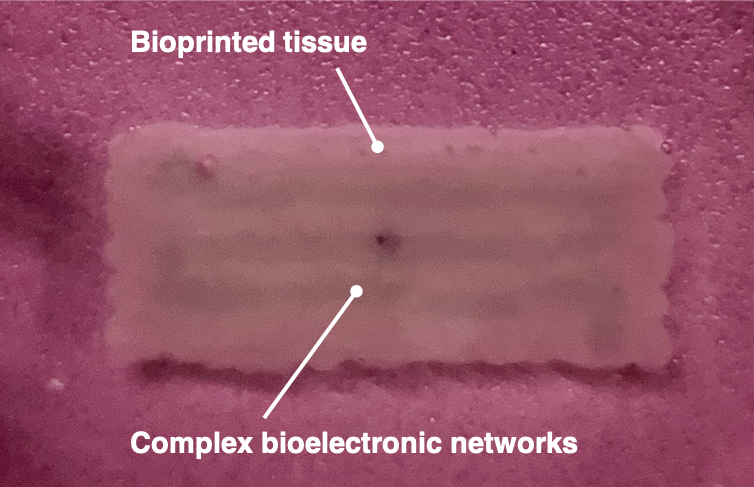

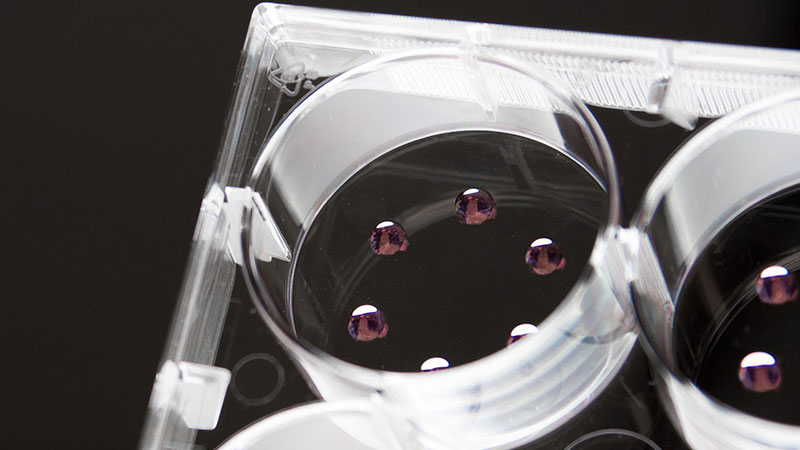

Unlike 3D printers, bioprinters are designed to print biological materials, or bioinks. Bioinks are typically laden with living human or mammalian cells. The bioprinting process usually involves using scaffolds or crosslinking to ensure constructs develop successfully and mimic target tissues in structure and function.

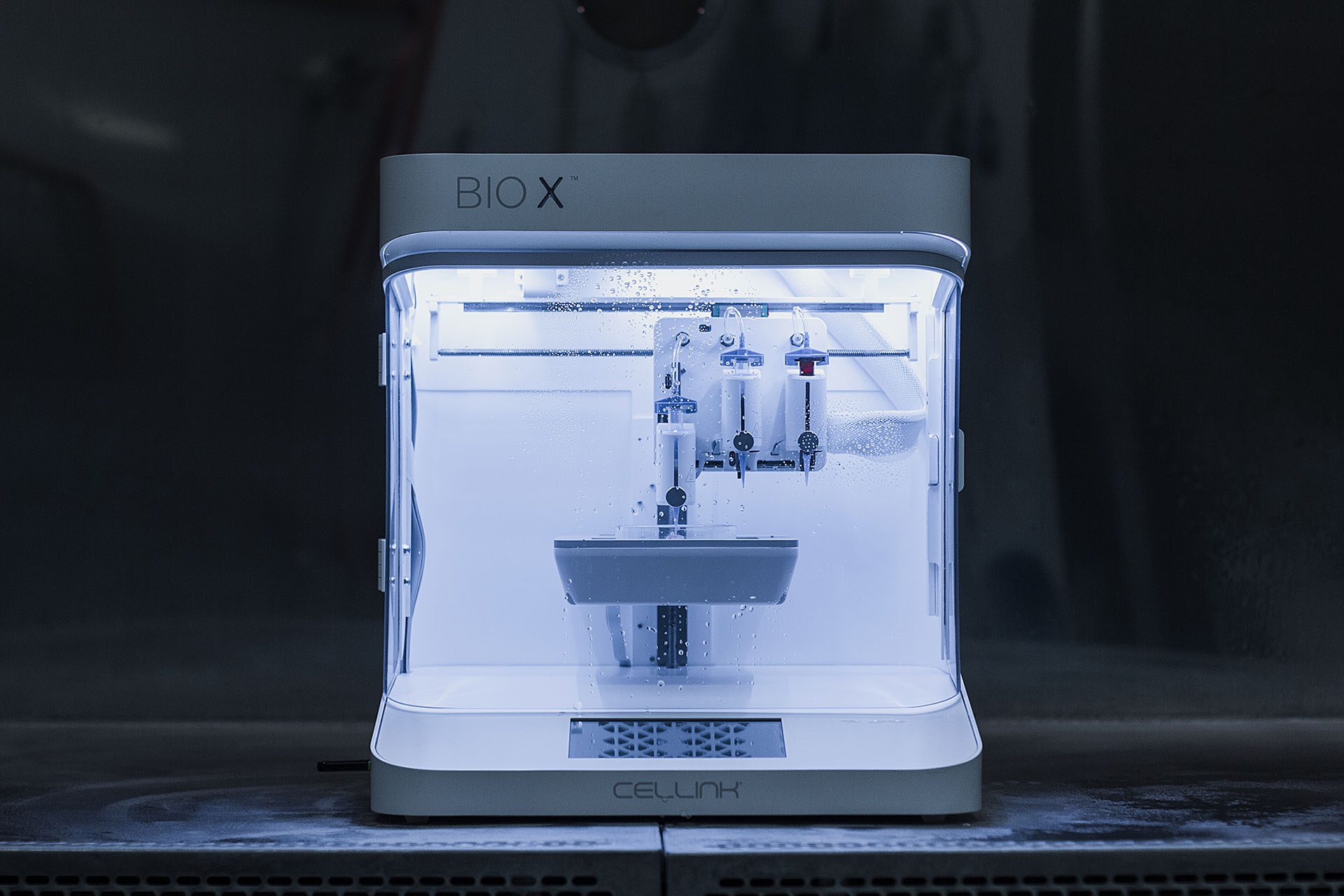

Most 3D printers extrude molten plastic that hardens to become a 3D object. Unlike 3D printers, bioprinters are designed to print liquid and gel-based materials, and can additionally perform noncontact droplet printing. They can print anything from Matrigel to molasses to thicker pastes – opening up additional applications within the food industry.

The bioprinting field continues to grow as technologies rapidly advance, and many diverse applications are coming into focus. Given the progress and practicality of the technology, it’s important that students are exposed to intuitive tools like the BIO X to prepare for careers in healthcare, agriculture, green technology and more.